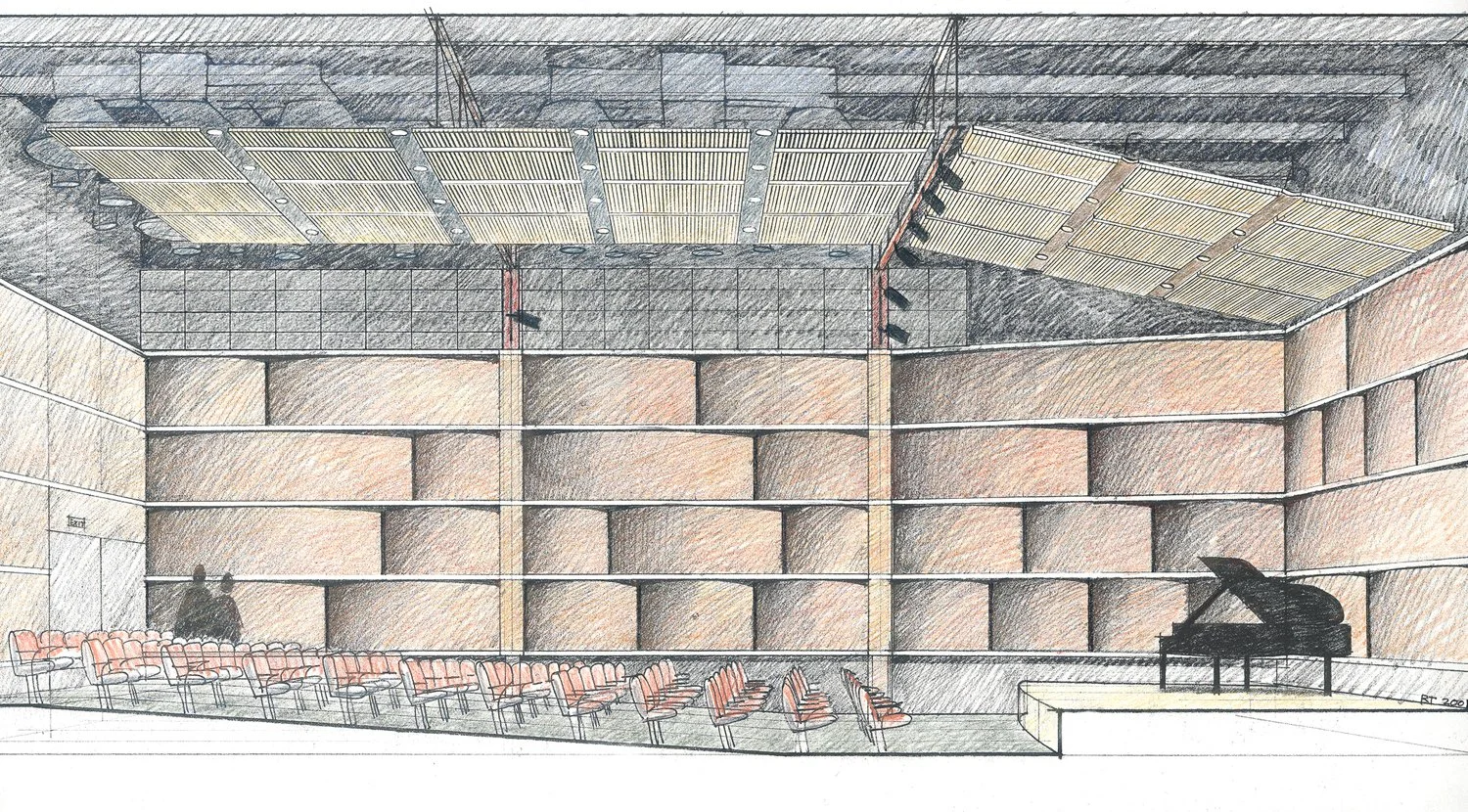

Salem State University Recital Hall

-

Salem, MA

Salem State University

July 2004

-

Recital Hall, 2004

Recital hall, backstage areas, practice rooms, and faculty - 3,000 sf

Renovation of 3,000 sf factory boiler plant into 200-seat recital hall

Support spaces include backstage Green Room, instrument storage, and lobby

Performing Arts Feasibility Study, 2000

Space needs and fit test for Theater and Music Departments - 67,000 sf

-

The university’s primary space for music and theater performance and teaching, this room is an instrument of music. Embodying concepts of musical structures, the walls are fabricated of “fiddle back” mahogany veneer (like a violin). The proportions teach concepts of musical ratios–wholes, thirds, and fifths–and suggest bars and staffs as well as strings and frets. The panels also impart desired acoustic properties and provide interstitial spaces for new mechanical and electrical systems. Seating 200 people, the room acoustics perform within one-tenth a second of design parameters.

An initial DCAMM-certified study develops a detailed space needs assessment and evaluates potential fit within the 67,000 sf building, a former light bulb factory. The programming effort includes interviews with faculty and staff, analysis of curriculum and facilities in use, and review of the University’s goals for education and campus life. A Room Data book details the function, character, equipment, and service expectations for every needed space.

Taylor & Burns is design architect, with expertise in performing arts and higher education, with ICON Architecture as prime architect of the overall project.

-

Adaptive reuse of an existing building

The Recital Hall is part of an extensive brownfield reclamation and building reuse project.

The building envelope is totally re-lined with thermal and vapor barrier to conserve energy, exceeding energy code requirements

Voluminous fresh air needs are mitigated by energy-efficient HVAC system: CO2 levels trigger fresh outdoor air intake that is tempered with energy recovered by heat-exchangers from the exhaust airstream

Fiddleback panels are made of thin veneers of sustainably-harvested mahogany laminated to a substrate of rapidly-renewable cellulose fiberboard

Carpet is 95% recycled content

-

Honor Award for Design Excellence

Boston Society of Architects, 2008